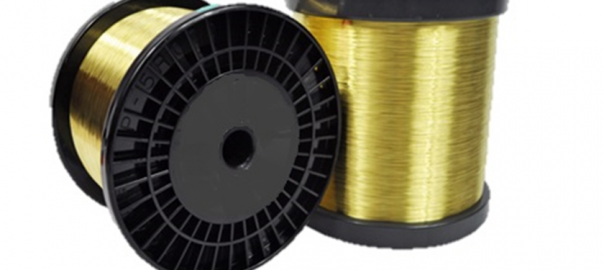

Quality Welding Wire

The Importance of Using Quality Welding Wire

When you’re operating a production line, the finished quality of the product is very important when it comes to the overall success of your project. A significant amount of time will be spent on the planning and developing phase of your project, which often includes narrowing down the exact specifications such as welding parameters for each part used in the process. Although this is a very important step in the process, one must first consider using a quality welding wire in order to really be successful.

Below, we take a deeper look into how welding wire feed speed and quality welding alloys can affect the finished weld on your project.

Welding Wire Feed Speed

In MIG welding, the wire feed speed (WFS) determines the current used to create the weld. Much like voltage, a WFS that is too high will create a bead that will sit on the surface of the piece and create excessive spatter requiring significant cleanup, as well as an excessively wide bead with poor penetration and a strong possibility of burn through.

If the WFS is too low, you will end up with a narrow bead that can take a concave shape, also requiring a lot of extra grinding and clean up. In general, a 1/4″ to 3/8″ electrode extending from the tip is about right, but will often be further tested and documented by the welding engineer supervising the settings and specifications.

Controlling the variables in your welding parameters can make a big difference in the quality of your completed welds and the finished product as a whole. When lesser quality welding wires are used it can often damage your project and/or equipment, wasting time and resources on your projects.

Here at Bob Martin Co, we pride ourselves in offering superior quality welding wire to meet the challenges faced by the customers within the industry. Take a look at our collection of welding wire. If your current welding wire and/or equipment isn’t up to the task of providing welds within your parameters and you’re considering purchasing new welding wire, please contact us today.