Looking for precision, consistency, and superior performance in your wire products? Centerless grinding plays a major role in achieving flawless tolerances and smooth finishes across aerospace, medical, industrial, and specialty manufacturing.

Looking for precision, consistency, and superior performance in your wire products? Centerless grinding plays a critical role in achieving flawless tolerances and smooth surface finishes across aerospace, medical, industrial, and specialty manufacturing applications. When even the slightest variation can affect performance, reliability, or safety, centerless grinding ensures the exact dimensions and finishes required for demanding environments.

Centerless grinding is a specialized process that removes material from the outside diameter of wire without the need for traditional centers or fixtures. Instead, the wire is supported between a grinding wheel and a regulating wheel, allowing for continuous, highly accurate processing. This method produces exceptional roundness, straightness, and surface quality while maintaining tight tolerances throughout the entire length of the wire.

Industries that depend on precision components rely heavily on centerless grinding services. In aerospace applications, wire must meet strict standards for strength, uniformity, and durability. Medical device manufacturers require ultra-smooth finishes and exact dimensions to ensure patient safety and product reliability. Industrial and specialty manufacturers also benefit from the consistency and efficiency that centerless grinding provides, especially for high-volume production runs or complex material requirements.

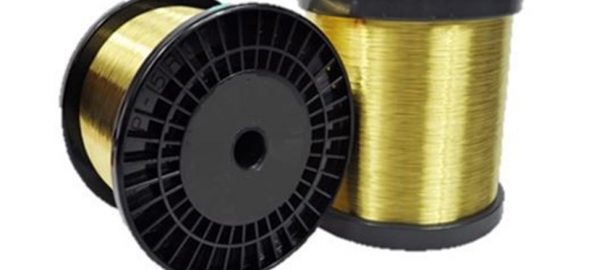

One of the biggest advantages of centerless grinding is its ability to handle a wide range of materials and wire sizes. Whether working with stainless steel, nickel alloys, copper, or specialty metals, the process delivers uniform results with minimal waste. It also improves surface integrity, reduces friction, and enhances the overall performance of the finished product.

At Bob Martin Company, centerless grinding wire services are performed with advanced equipment and strict quality control standards. Decades of experience in wire processing allow the team to deliver precise tolerances, consistent finishes, and dependable results for even the most demanding applications. From prototype runs to full-scale production, every order is handled with attention to detail and a commitment to quality.

When your project demands tight tolerances and top-tier wire processing, partner with the experts at Bob Martin Company. Contact the team today to learn more about their centerless grinding capabilities and how they can support your next high-performance application.

Is this conversation helpful so far?